Rules of resilience: Securing supply chains in a fast-moving world

"Physical trade routes and financial systems are more connected than ever, meaning disruption is now a key part of how the world works."

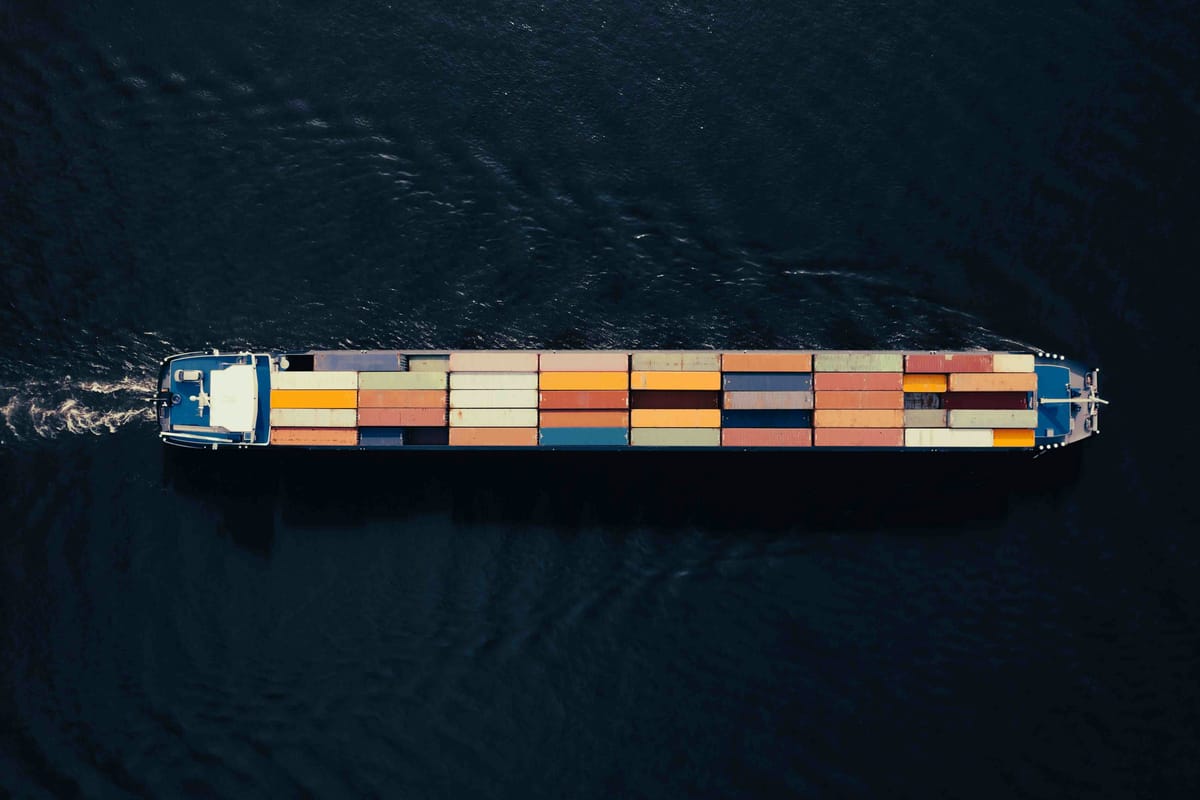

Supply chains are being tested like never before. From blocked shipping routes to changing tariffs, disruption now hits faster than most businesses can blink. Traditional contingency plans are no longer enough. To keep up, supply chains need to be built on live data and real-time decisions - not just to handle problems, but to stay ahead of the competition.

Disruption is the default

Recent events like shipping delays in the Red Sea, export controls on semiconductors and rising tariffs have exposed just how exposed global supply chains really are. These challenges aren’t just one-offs. When physical trade routes and financial systems are more connected than ever, disruption is now an inherent part of how the world works.

When regulations change overnight or routes are suddenly blocked, slow or disconnected systems make it difficult to respond. The businesses best placed to adapt are those that already have clear visibility across their supply chain and the tools to model and test the impact of change in real time.

From reactive to predictive

Artificial intelligence (AI) and predictive analytics allow businesses to get ahead of disruption, rather than simply reacting to it. Machine learning tools can flag early warning signs, from weather-related port delays to a drop in supplier performance, giving operational teams the foresight to pivot, not just to respond.

At the same time, predictive models simulate what-if scenarios and model their impact across the supply chain. What happens if tariffs increase on key components? What’s the cost of switching suppliers? How might currency volatility affect procurement costs? Having answers to these questions in advance helps build resilience into daily operations.

Yet, Qlik’s latest research shows nearly one in ten companies do not use any internal data to navigate tariff-related challenges. Meanwhile, 40% are held back by incomplete data when trying to respond. In a world where disruption is a near daily occurrence, that’s a big risk.

Resilience in practice

Across industries, we’re seeing what good looks like. Logistics teams are combining vehicle tracking, inventory visibility and customer demand signals into a single, dynamic view, helping to reduce delays and cut operational waste. Retailers are improving how they forecast and respond to customer demand.

In manufacturing, predictive maintenance powered by AI helps keep equipment running and production schedules on track. In the energy and resources sector, predictive models can forecast geopolitical or environmental threats that would otherwise blindside planning teams.

These aren’t one-size-fits-all solutions, and they don’t require a whole tech stack overhaul. But what they have in common is the ability to make quicker, better-informed decisions using data that’s already available - just more effectively applied.

Success depends on speed

What makes today’s challenges harder is how quickly they unfold. When tankers backed up in the Strait of Hormuz, markets reacted within hours - oil prices rose, and freight routes shifted. A tariff decision or a rail failure can affect delivery schedules or input costs within hours. Long planning cycles and lagging reports no longer offer enough protection.

That’s why resilience today is defined not just by infrastructure or inventory buffers, but by how fast you can make an informed decision. The faster your business can respond, the more resilient you’ll be.

The best place to start is with one weak spot. From there, businesses can assess the quality and speed of the data they’re using to manage that risk. Strengthening one area often reveals opportunities to apply the same approach more broadly, laying the groundwork for a more responsive and resilient supply chain.

Martin Tombs is VP of Go to Cloud at Qlik